CircuitSolver (CS)

For decades, balancing has been the combined effort of several contractors spending a lot of time manually balancing and rebalancing a Domestic Hot Water System (DHWS) to achieve the required flow needed to obtain the same temperature in each branch.

While manual balancing methods are good in theory, they flounder in practice resulting in hefty labor costs and frequent callbacks due to a manual balancing valve’s inability to react to dynamic changes in the system.

To conquer the challenges inherent to conventional manual balancing methods, ThermOmegaTech® invented the CircuitSolver®, the market’s first thermostatic balancing valve for domestic hot water recirculation systems.

Have Questions?

Ready to Buy?

How It Works:

Installed at the end of each branch or riser before the return, CircuitSolver® uses our unique Thermoloid® wax thermal actuator to modulate the valve open and closed in response to temperature variations to maintain a specified temperature in each branch/riser.

During the initial start-up of a Domestic Hot Water System (DHWS), the valve is wide open and will begin to close once the system temperature requirements are met. Once the system is balanced, the valve will remain in its closed* position to keep hot water in the line and only modulate open to establish flow when the water temperature drops below the valve’s set-point. The CircuitSolver® will automatically modulate to its closed* position once the water temperature returns to the desired temperature.

This automatic response to temperature allows the balancing valve to adjust dynamically to the varied usage rates in a DHWS throughout the day. No manual balancing is required, simply install the valves and watch them work!

*Note: The valve will never fully close, allowing a small flow bypass to the return to avoid dead-heading the recirculation pump. The limited flow to your return line will reduce system wear, electricity, and water usage and improve overall system operation.

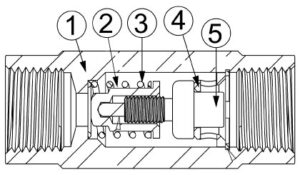

Valve Components:

The CircuitSolver® thermostatic balancing valve is comprised of 100% high-quality stainless steel components – a valve body, valve plug, spring, carrier, and thermal actuator.

| ITEM | DESCRIPTION | MATERIAL |

| 1 | Valve Body | 300 series stainless steel |

| 2 | Valve Plug | 300 series stainless steel |

| 3 | Spring | 300 series stainless steel |

| 4 | Carrier | 300 series stainless steel |

| 5 | Thermal Actuator | 300 series stainless steel |

Typical Applications:

CircuitSolver® can be used in any building with a domestic hot water recirculation system to maintain a thermally balanced approach and have hot water readily available at each fixture. Used in commercial buildings of all sizes and Domestic Hot Water Systems (DHWS) with varying complexity, CircuitSolver® installations often include hotels, hospitals, universities, high-rise, and multi-family apartment buildings.

To see CircuitSolver® installations in your area, visit our installations page.

CircuitSolver® thermostatic balancing valves can also balance the return flow between the master mixing valve and the water heater. To learn more about this application, go to the Balancing a DHWS Return with CircuitSolver page.

Benefits:

- All Stainless Steel – Corrosion Resistant Construction

- High thrust actuator keeps orifice free of debris

- Never fully closes, some water always passing through

- Long service life and 10-year warranty

- Reduces installation and maintenance costs

- Promotes effective water conservation

Certifications:

- NSF/ANSI/CAN 61 & 372 Certified

- Lead Free

- Fully compliant with Section 1417(d) of SDWA, the Safe Drinking Water Act

- Supports efforts toward LEED Certification

- Complies with the Buy American Act

Specifications:

- Sizes: 1/2”, 3/4″, 1”, 1 ¼”, 1 ½”, & 2”

- Fixed Temperatures:

- 100°F (37.7°C)

- 105°F (40.5°C)

- 110°F (43.3°C)

- 115°F (46.1°C)

- 120°F (48.8°C)

- 125°F (51.6°C)

- 130°F (54.4°C)

- 135°F (57.2°C)

- 140°F (60.0°C)

- Max Working Pressure: 200 PSIG (14 BAR)

- Max Working Temperature: 250°F (121°C)

CircuitSolver® is a great product - I have never used anything like it. Robert Schrieber Maintenance Manager at Embassy Suites in Brunswick, GA

The University of South Florida - On startup of this install, the system automatically balanced itself in under 3 hours, all without manual labor thanks to CircuitSolver®. The plumbers actually went out a did another job, went to breakfast, and when they came back, the system was balanced. Mike Bishop V.P. of Engineering at RGD Consulting Engineers in Jupiter, FL

Before we installed CircuitSolver®, we would have wait times between 5-7 minutes for hot water on the higher floors. Since we’ve installed CircuitSolver®, we have been getting hot water when needed and have not had a single complaint. It’s a great product; I’ve never used anything like it. Robert Schrieber Maintenance Manager, Embassy Suites in Brunswick, GA

Install it and save yourself the headache; CircuitSolver® is in a league of its own. Adam Podway Project Manager, Gorman-Lavelle Corp, for UH St. John’s Medical Center, Westlake, OH

I haven’t come across another product like CircuitSolver®. Once you install them, you never have to adjust them, unlike manual balancing valves where you must balance every single valve you install. Employee – Da Vinci Project for GJM Engineering, Los Angeles, CA

I recommend CircuitSolver® to anyone who wants to listen; they won’t be disappointed. Once installed, there will be no reason to return to them for maintenance. CircuitSolver® eliminates the amount of work you must do in the field. Joe Sargent Onsite Plumbing Superintendent of W.E. Bowers, for new eCommerce HQ2, Arlington, VA

What an awesome little device these guys make. It’s a no-brainer. Andy Crossland Principal Mechanical Engineer at Crossland Engineering LLC in Honolulu, HI

CircuitSolver® is a great product - I have never used anything like it. Robert Schrieber Maintenance Manager at Embassy Suites in Brunswick, GA

Rittenhouse Hill Apartments - We had a very complicated apartment restoration involving 47 risers. CircuitSolver® saved a lot of time, installed easily, used smaller recirculation pumps to save energy & wear, and continues performing well. Ron Miller President at Adelphia Plumbing in Philadelphia, PA

CircuitSolver® was able to automatically balance the system when engineers could not. Mark Wilmink MarkCo Plumbing in Florence, KY

Simply stated, CircuitSolver® valves are easy to install and work very well with no issues to date. They’re efficient and take the time typically required to manually balance systems at the end of the project out of the equation. Christopher Meurer Plumbing Operations Manager at J.C. Cannistraro, LLC in Boston, MA

I haven’t come across another product like CircuitSolver®. Once you install the valves you never have to adjust them, unlike manual balancing valves where you have to balance every single valve you install. Richard Parker Plumbing Contractor at Pan-Pacific Mechanical in Fountain Valley, CA

CircuitSolver®, being that it is an automatic balancing valve, just makes the job of balancing an intricate hot water system that much easier. David Texter Plumbing Engineer at Browne Engineering in Cincinnati, OH

Ordering the assembled CircuitSolvers allowed ICS to use less jobsite manpower and enabled us to install every balancing valve correctly. Time to tap, I have never seen a building so consistently deliver hot water that fast! I’m impressed with the whole system. Ed Parisi Plumbing Design Manager at Industrial Commercial Systems, for LEGOLAND® Castle Hotel, Carlsbad, CA

CircuitSolver® is a great product. The valves automatically adjust to changing temperatures and pressure drops unlike manual and automatic balancing valves. Plumbing Contractor Production Plus Plumbing in Vista, CA

Using CircuitSolver® makes balancing the system so easy. The valves automatically adjust themselves, so you don’t have to check each valve once installed, and there are never any callbacks for issues. Arturo Hernandez GJM Engineering in Los Angeles, CA

We’ve used CircuitSolver®s exclusively now for several years in every application we can. Simply stated, the product is easy to install and works very well with no issues to date. Christopher Meurer Plumbing Operations Manager at J.C. Cannistraro, LLC in Boston, MA

The Da Vinci Project - By using CircuitSolver® balancing valves, we were able to save both time and money. The start-up process was much faster by not having to manually adjust each valve. After installation, the system balanced itself and required no maintenance. Arturo Hernandez GJM Engineering in Los Angeles, CA

I would tell any contractor, building engineer, and mechanical engineer if you are looking at CircuitSolver®, it is simple, it is easy to use, and it works right from the get-go. Chris Watts Plumbing Service Manager at Braconier in Denver, CO

USC Villages Student Housing - By using CircuitSolver®valves, we saved time and money by not having to balance the system or make any adjustments. It made the process much easier and smoother. Richard Parker Plumbing Contractor at Pan-Pacific Mechanical in Fountain Valley, CA

Right after the installation the general manager went around the building and there was a noticeable difference with quick delivery of hot water. Andy Crossland Principal Mechanical Engineer at Crossland Engineering LLC in Honolulu, HI

When we install CircuitSolver® valves, it corrects the client’s hot water circulation problems, and everything operates as it’s designed. We are going to keep installing them. Jason Putnam Project Manager at Douglas ORR Plumbing in Miami Springs, FL

CircuitSolver® makes the initial startup so easy. When we turned it on, the valves balanced the whole system without us having to make any adjustments. We never have any issues when installing them in our projects. Plumbing Contractor Production Plus Plumbing in Vista, CA

CircuitSolver® makes balancing the system so easy. We don’t have to manually set each line or make any adjustments. We have had absolutely no balancing issues since we started up the system. Richard Parker Plumbing Contractor at Pan-Pacific Mechanical in Fountain Valley, CA

The advantages of the system are an efficiently balanced system, saving time testing and balancing the system, lower utility bills and reduced water usage. Luke Holding Project Engineer at The Beck Group in Dallas, TX

I try to have CircuitSolver® specified on as many jobs as possible due to the simplicity of it. Eric McTee Plumbing Designer at ME Engineering in Golden, CO

CircuitSolver® valves are efficient and take the time typically required to manually balance systems at the end of the project out of the equation. We have started up systems in the afternoon to come in the next morning to find hot water perfectly balanced throughout all risers and zones. Christopher Meurer Plumbing Operations Manager at J.C. Cannistraro, LLC in Boston, MA

By eliminating the conventional method of using fixed flow balancing valves and installing CircuitSolver® valves instead we were able to resolve our lack of hot water in some sectors of the hospital issue instantly. André Renaud Building Consultant at Mental Health University Institute of Quebec

It was taking over a minute and a half to get hot water, and now it’s down to 15-20 seconds…also a huge conservation of water…it was a fairly simply retrofit. Robert Albanese Owners Representative for The Austonian in Austin, TX

It usually takes 2-3 plumbers, 2-3 days to balance a system of this size, but by using CircuitSolver® this process was done instantly. Huge savings in terms of time and effort typically devoted to the balancing process. Stephan Thompson Plumbing Contractor at E.M. Duggan Inc. in Canton, MA

Before CircuitSolver®, we would have wait times between 5-7 minutes for hot water on the higher floors. Since we have installed CircuitSolver® valves, we are getting hot water when we need it and have not had a single complaint. Robert Schrieber Maintenance Manager at Embassy Suites in Brunswick, GA

CircuitSolver® is a game changer in balancing DHWS and I would definitely use it as a standard in future projects. Matt Trevino Plumbing Engineer at DBR Engineering in San Antonio, TX